Revolutionizing Comfort: The Shoe Insole Machine

Are you tired of uncomfortable shoes causing you pain and discomfort? Introducing the groundbreaking technology of the Shoe Insole Machine, revolutionizing the way we experience comfort in our footwear. This innovative device is changing the game for those in search of the perfect fit and support for their feet. Read on to discover how this incredible invention is transforming the way we think about shoe comfort and revolutionizing the way we walk.

- Introducing the Shoe Insole Machine: A Game-Changer in Comfort

Introducing the Shoe Insole Machine: A Game-Changer in Comfort

In today’s fast-paced world, comfort is key. Whether it’s in the home, the office, or out and about, people always seek ways to enhance their comfort levels. When it comes to footwear, the right insole can make all the difference in providing superior comfort and support. This is where the shoe insole machine comes into play, revolutionizing the way insoles are made and providing a game-changing solution for a more comfortable and personalized fit.

The shoe insole machine is a cutting-edge technology that is transforming the way insoles are crafted. Unlike traditional methods that involve manual labor and take a significant amount of time, this machine automates the entire process, making it faster, more efficient, and highly precise. With the use of advanced scanning and 3D printing technology, the shoe insole machine is able to create custom insoles tailored to each individual’s unique foot shape and arch support needs.

One of the key benefits of the shoe insole machine is its ability to provide a personalized fit. By scanning the foot and analyzing its shape and pressure points, the machine can create insoles that offer targeted support exactly where it’s needed. This level of customization not only ensures a more comfortable fit but also helps to alleviate common foot issues such as plantar fasciitis, flat feet, and high arches.

Furthermore, the shoe insole machine is a game-changer in terms of material innovation. Traditional insoles are often made from generic materials that may not provide the best support or cushioning. In contrast, the shoe insole machine allows for the use of advanced materials, such as memory foam, gel, and carbon fiber, to create insoles that are not only comfortable but also durable and long-lasting. This means that wearers can expect superior comfort and support for an extended period of time, without the need to frequently replace their insoles.

In addition to its personalized fit and advanced materials, the shoe insole machine also offers a level of convenience that is unmatched by traditional insole crafting methods. With its quick and automated process, individuals can have custom insoles made in a fraction of the time it would take using traditional methods. This means that they can enjoy the benefits of superior comfort and support without having to wait weeks for their insoles to be made.

The shoe insole machine is also a sustainable solution for the footwear industry. By utilizing 3D printing technology, it minimizes waste and reduces the environmental impact of insole production. This aligns with the growing demand for sustainable and eco-friendly products, making the shoe insole machine a forward-thinking solution for both businesses and consumers.

In conclusion, the shoe insole machine is indeed a game-changer in comfort. With its personalized fit, advanced materials, convenience, and sustainability, it offers a new standard in insole production and sets a benchmark for the future of footwear comfort. As this innovative technology continues to gain traction, it’s clear that the shoe insole machine is not just a trend but a significant advancement in the quest for enhanced comfort and support.

- How the Shoe Insole Machine is Redefining the Footwear Industry

The footwear industry is being revolutionized by the shoe insole machine, a technology that is redefining comfort and performance for consumers around the world. This innovative machine is changing the way insoles are manufactured, creating a new standard of quality and customization in footwear.

The shoe insole machine is a cutting-edge technology that allows for the mass production of insoles with unparalleled precision and consistency. Traditionally, insoles were made by hand, a process that was time-consuming and often resulted in variations in quality. With the shoe insole machine, manufacturers are able to produce insoles quickly and efficiently, while maintaining a high level of precision and uniformity.

One of the key features of the shoe insole machine is its ability to create custom insoles tailored to the specific needs of each individual. This level of customization was previously only available through expensive and time-consuming methods, such as 3D printing. However, the shoe insole machine is able to create custom insoles in a fraction of the time and at a much lower cost, making personalized comfort accessible to a wider range of consumers.

Another significant advantage of the shoe insole machine is its impact on the overall comfort and performance of footwear. Insoles are a critical component of any shoe, providing support, cushioning, and stability. By utilizing the shoe insole machine, manufacturers are able to produce insoles that are designed to enhance the wearer's comfort and performance, resulting in a more satisfying and enjoyable wearing experience.

In addition to improving comfort, the shoe insole machine is also making significant strides in sustainability within the footwear industry. By streamlining the production process and reducing material waste, the machine is helping to minimize the environmental impact of insole manufacturing. This commitment to sustainability is an important step forward for the industry, as consumer demand for eco-friendly products continues to rise.

The impact of the shoe insole machine is not limited to manufacturers and consumers. Retailers are also reaping the benefits of this technology, as it allows them to offer a wider range of insoles and footwear options to their customers. With the ability to create custom insoles on demand, retailers can provide a level of personalization that was previously unheard of, resulting in increased customer satisfaction and loyalty.

As the footwear industry continues to evolve, the shoe insole machine is poised to play a significant role in shaping its future. With its ability to improve comfort, performance, and sustainability, this innovative technology is challenging the status quo and setting a new standard for insole manufacturing. As consumers increasingly prioritize comfort and customization in their footwear choices, the shoe insole machine is positioned to become an essential tool for manufacturers and retailers alike.

- The Technology Behind the Shoe Insole Machine: A Closer Look

Revolutionizing Comfort: The Shoe Insole Machine - The Technology Behind the Shoe Insole Machine: A Closer Look

In the world of footwear, comfort is key. As consumers become more conscious of the importance of foot health and overall comfort, the demand for high-quality shoe insoles has never been greater. This is where the shoe insole machine comes into play. This innovative technology is revolutionizing the way insoles are produced, providing a closer look at the intricate processes and technologies behind this game-changing machine.

The shoe insole machine is a marvel of modern engineering, designed to streamline the production of high-quality insoles with precision and efficiency. At the heart of this technology is the intricate system of components that work together seamlessly to create insoles that are tailored to the unique needs of each individual, providing unparalleled comfort and support.

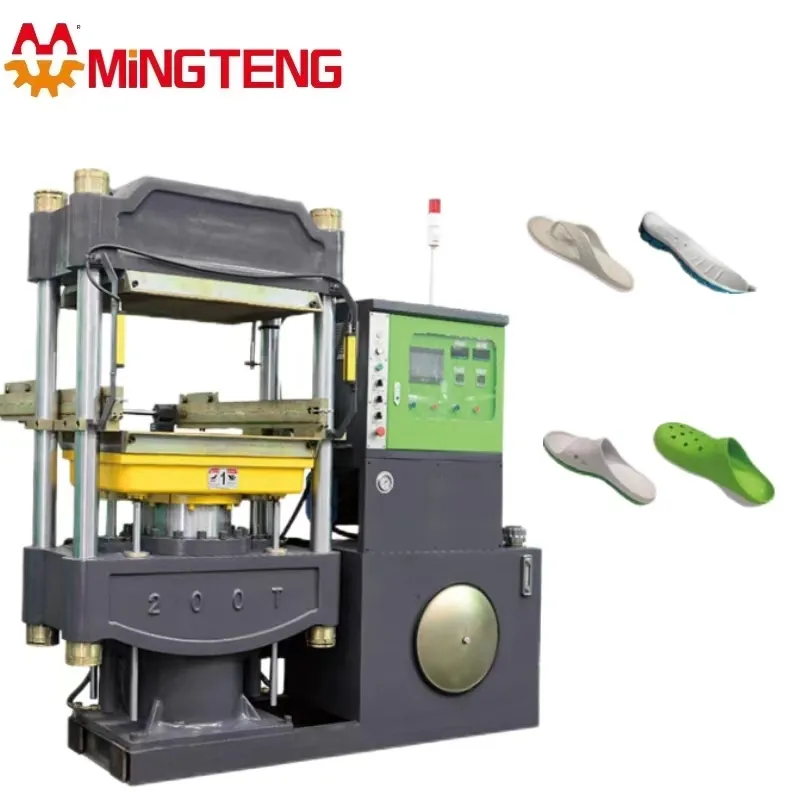

One of the key components of the shoe insole machine is the molding system. This part of the machine is responsible for creating the shape of the insole, utilizing advanced molding techniques to ensure a perfect fit for the wearer. The molding system is equipped with precise sensors and advanced software that allow it to adapt to the specific contours of the foot, resulting in a custom-made insole that provides optimal support and comfort.

Another crucial component of the shoe insole machine is the material dispensing system. This part of the machine is responsible for dispensing the materials that will form the insole, such as foam, gel, and other cushioning materials. The material dispensing system is equipped with advanced technology that ensures precise and uniform distribution of materials, resulting in insoles that are consistently well-cushioned and comfortable.

The cutting and shaping system is another essential component of the shoe insole machine. This part of the machine is responsible for cutting and shaping the insole to the specified dimensions, ensuring that each insole is precisely tailored to fit the shoe it is intended for. The cutting and shaping system is equipped with high-precision tools and advanced software that allow it to create insoles with exacting precision, resulting in a perfect fit every time.

In addition to these key components, the shoe insole machine is also equipped with advanced quality control systems that monitor every step of the production process. These systems are designed to detect any defects or irregularities in the insoles, ensuring that only the highest quality products make it to the market.

The shoe insole machine is truly a marvel of modern technology, redefining the way insoles are produced and setting new standards for comfort and support in footwear. With its advanced molding, material dispensing, cutting and shaping systems, this machine is able to create custom-made insoles that provide unparalleled comfort and support to the wearer.

In conclusion, the shoe insole machine is a game-changing technology that is revolutionizing the way insoles are produced. With its advanced components and meticulous attention to detail, this machine is setting new standards for comfort and support in footwear, providing consumers with insoles that are custom-made to fit their unique needs. As the demand for high-quality, comfortable footwear continues to grow, the shoe insole machine is poised to play a pivotal role in shaping the future of the industry.

- Benefits of Using the Shoe Insole Machine for Customized Comfort

The demand for customized comfort and support in footwear has led to the development of the shoe insole machine, a revolutionary tool that is changing the way people think about their shoes. This article will explore the benefits of using the shoe insole machine for customized comfort, and how it is revolutionizing the footwear industry.

One of the key benefits of using the shoe insole machine is the ability to create customized insoles that are tailored to the unique shape and contours of an individual's feet. This allows for a truly personalized fit, which can significantly improve comfort and support. Unlike generic insoles that are designed to fit a wide range of foot shapes, customized insoles produced by the shoe insole machine are created specifically for the individual wearer, taking into account factors such as arch height, foot length, and gait pattern.

Furthermore, the shoe insole machine offers a wide range of materials and cushioning options, allowing users to select the level of support and comfort that best suits their needs. Whether the wearer requires extra cushioning for high-impact activities such as running or sports, or a firmer support for everyday use, the shoe insole machine can produce insoles that meet these specific requirements. This level of customization ensures that the insoles not only provide maximum comfort, but also help to prevent common foot problems such as plantar fasciitis and overpronation.

In addition to the personalized fit and material options, the shoe insole machine also offers the convenience of on-the-spot production. Instead of waiting for insoles to be shipped from a factory, users can have their customized insoles produced in a matter of minutes, right in the store or at a podiatrist's office. This eliminates the need for lengthy waiting times and ensures that the insoles can be tested and adjusted immediately for maximum comfort and effectiveness.

Furthermore, the shoe insole machine is environmentally friendly, as it reduces waste by only using the materials needed for each individual insole. This is in stark contrast to traditional insole production methods, which often result in excess materials being discarded. By producing insoles on-demand, the shoe insole machine helps to minimize the environmental impact of insole production and reduce the carbon footprint of the footwear industry.

Overall, the shoe insole machine is revolutionizing the way individuals think about comfort and support in their footwear. By offering personalized fit, a wide range of material options, on-the-spot production, and environmental benefits, this innovative tool is changing the game for both consumers and the footwear industry as a whole. Whether it's for athletic performance, everyday comfort, or foot health, the shoe insole machine is paving the way for a new standard of customized comfort in footwear.

- The Future of Footwear: Exploring the Potential Impact of the Shoe Insole Machine

The Future of Footwear: Exploring the Potential Impact of the Shoe Insole Machine

In the ever-evolving world of footwear, technology continues to play a crucial role in enhancing comfort and performance. One of the latest innovations in this field is the shoe insole machine, a cutting-edge device that has the potential to revolutionize the way we think about footwear. This article will explore the implications of this groundbreaking invention and its possible impact on the future of footwear.

The shoe insole machine is a state-of-the-art device that is designed to create custom insoles for individual users. By using advanced scanning technology, the machine is able to analyze the unique contours and pressure points of a person's foot. This data is then used to create a customized insole that provides optimal support and comfort. This level of personalization has the potential to significantly improve the overall fit and feel of footwear, leading to enhanced performance and reduced risk of injury.

One of the key benefits of the shoe insole machine is its ability to address a variety of foot-related issues. From arch support to pressure distribution, the machine can be tailored to meet the specific needs of each individual. This level of customization can be particularly beneficial for athletes and individuals with foot conditions such as plantar fasciitis or pronation. By providing targeted support in the areas where it is needed most, the shoe insole machine has the potential to alleviate discomfort and improve overall foot health.

Furthermore, the shoe insole machine has the potential to revolutionize the way footwear is designed and manufactured. Traditionally, insoles are mass-produced and inserted into shoes during the manufacturing process. This one-size-fits-all approach often leads to inconsistencies in fit and comfort. However, with the introduction of the shoe insole machine, it is now possible to create custom insoles that are specifically tailored to the design of a particular shoe. This level of integration has the potential to enhance the overall performance and comfort of footwear, leading to a new standard in the industry.

In addition to its impact on individual consumers, the shoe insole machine also has significant implications for the footwear industry as a whole. By offering a new level of customization and personalization, this technology has the potential to disrupt traditional manufacturing processes and supply chains. As more companies adopt this technology, it is likely that the production of custom insoles will become more streamlined and cost-effective. This, in turn, has the potential to reshape the way footwear is designed, manufactured, and distributed on a global scale.

As with any new technology, there are still challenges and limitations to consider. The cost of implementing and maintaining the shoe insole machine may present a barrier for some consumers and manufacturers. Additionally, there may be a learning curve for designers and engineers as they adapt to this new approach to footwear customization. However, with continued research and development, these challenges are likely to be addressed, paving the way for a new era in footwear design and innovation.

In conclusion, the shoe insole machine has the potential to revolutionize the way we think about footwear. By offering a new level of customization and personalization, this technology has the potential to enhance comfort, performance, and overall foot health. Additionally, its impact on the footwear industry could lead to new standards in design and manufacturing. As this technology continues to evolve, it is likely that the shoe insole machine will play a pivotal role in shaping the future of footwear.

Conclusion

In conclusion, the shoe insole machine has truly revolutionized the way we approach comfort in footwear. By combining advanced technology with customization options, manufacturers are able to create insoles that cater to the specific needs and preferences of individual customers. This not only enhances the overall comfort and support of the shoe, but also contributes to better foot health and overall well-being. As the demand for personalized products continues to grow, it is clear that the shoe insole machine will play a crucial role in the future of footwear manufacturing. With its ability to offer a tailored approach to comfort, this innovative technology is set to change the game for both consumers and the industry as a whole. The days of one-size-fits-all insoles are behind us, and the era of customized comfort is here to stay.