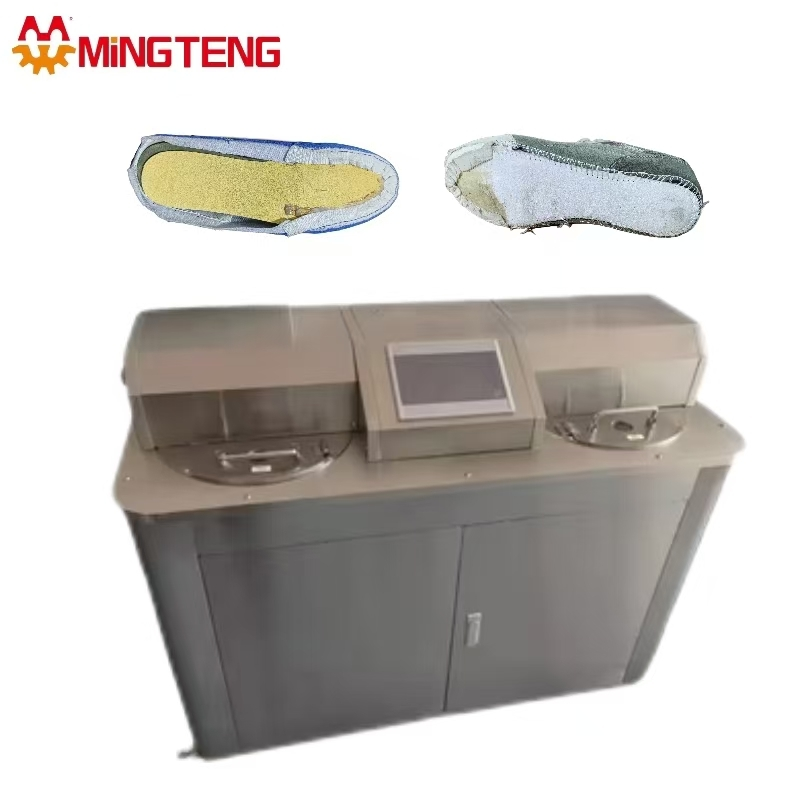

MT-198 Double Barrel Intelligent Glue Brushing Machine/Double Bucket Glue Machine Gluing Machine

Double Bucket Glue Machine

1.Designed with two separate barrels, the machine allows for the simultaneous storage and dispensing of two different types of glues or coatings. This feature significantly enhances production flexibility, enabling manufacturers to quickly switch between materials or even apply dual coatings in a single pass. It eliminates the need for frequent material changes and downtime, thereby boosting overall productivity.

2.The machine is equipped with precision glue heads or coating devices that ensure uniform and consistent glue application. This not only enhances product aesthetics but also improves product durability and functionality by ensuring that glue is applied precisely where it is needed.

3.In terms of maintenance, the machine is designed for ease of use and accessibility. Its components are easily removable and cleanable, allowing for quick and efficient maintenance routines. This extends the machine's lifespan and minimizes downtime due to unexpected breakdowns.

4.The Dual-Barrel Smart Glue/Coating Machine is often equipped with eco-friendly and energy-saving features. These include low-energy motors, sealed glue containers, and other innovations that minimize energy consumption and reduce the environmental impact of the gluing or coating process

Advantages

Dual-Barrel Design: The innovative dual-barrel configuration allows for simultaneous storage of two distinct types of glue or coating materials. This enhances flexibility and versatility, especially beneficial for processes requiring frequent material changes or dual-coating applications.

Intelligent Control System: Equipped with an advanced intelligent control system, the machine achieves precise control over glue dispensing volume and speed. By pre-setting programs or adjusting parameters in real-time, it meets the diverse gluing requirements of various products and processes.

High-Precision Glue Application: Featuring precision glue heads or coating devices, the machine ensures a uniform and consistent coating of glue on the target surface. This not only enhances product quality but also minimizes glue waste and reduces the incidence of defective products.

Automated Operation: The Dual-Barrel Smart Glue/Coating Machine is designed for automated operation, streamlining processes such as glue transfer, application, and cleaning. This reduces manual labor, enhances productivity, and promotes workplace safety.

Ease of Maintenance: The machine is engineered with easily removable and cleanable components, facilitating routine maintenance and care. This extends the machine's lifespan and minimizes downtime due to unforeseen breakdowns.

Eco-Friendliness and Energy Efficiency: With a focus on sustainability, some models incorporate eco-friendly and energy-saving features, such as low-energy motors and sealed glue containers. These minimize energy consumption and reduce the environmental impact of glue evaporation.

Multi-Functionality: Beyond basic gluing and coating functions, these machines often offer additional capabilities like glue heating, temperature control, and viscosity adjustment. These enhanced features further expand the machine's applicability and flexibility in various industrial settings.

Key attributes

| Applicable Industries | Manufacturing Plant,Other | Weight (KG) | 130 |

| Showroom Location | None | Video outgoing-inspection | Provided |

| Machinery Test Report | Provided | Marketing Type | Ordinary Product |

| Warranty of core components | 1 Year | Core Components | Engine,Bearing,Motor,Pressure vessel |

| Place of Origin | Fujian,China | Warranty | 1 Year |

| Condition | New | Brand Name | MingTeng |

| Brand | MT | Useful | Shoes Making |

| Color | Customers'Demand | Key words | Shoe Machine Industry |

| Shipping | 15days | After Warranty Service | Technical Video Support |

| Machine | Shoe Machine Line | DIMENSION | 136*60*110CM |

Customization