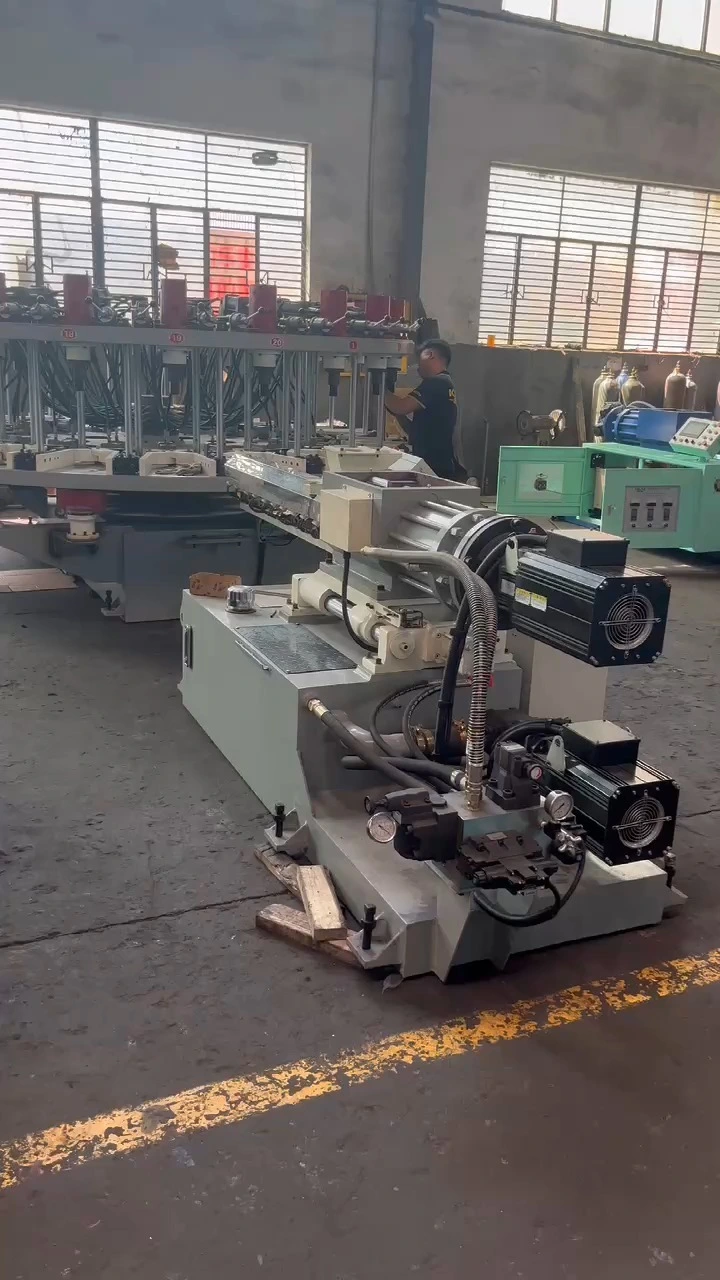

MT-5112YY Full-Automatic Disc Type Single(Double) Color Casual Shoes Sports Shoes Knot Injection Molding Machine

Injection Molding Machine

1. All oil circuits are controlled proportion pressure to coordinate with computer digital feeding system.

2. Hydraulic compare with vertical straight locking device for perfect tightness with the least burr, to reduce repair time as well as manufacture cost.

3. Coordinated with electric and hydraulic structure and unique braking device to make rotary turn fast and set precisely.

Advantages

2.Central circulating cooling water supply makes the mold on good cooling system.

3. It is adjustable according to the height of shoe last. Special toecap setting racks are available for simple and fast change of molds.

4. Molds on each station are provided with water-cooling system to minimize greatly the time required for perfect formation of finished products and achieve the purpose of better productivity.

5.Injection can be completed instantly under high pressure and have injection stop device which can save injection time, increase speed of circulate period and promote production capacity.

Key attributes

| Applicable Industries | Manufacturing Plant,Other | Weight (KG) | 8500 |

| Showroom Location | None | Video outgoing-inspection | Provided |

| Machinery Test Report | Provided | Marketing Type | Ordinary Product |

| Warranty of core components | 1 Year | Core Components | Engine,Bearing,Motor,Pressure vessel |

| Place of Origin | Fujian,China | Warranty | 1 Year |

| Condition | New | Brand Name | MingTeng |

| Brand | MT | Useful | Shoes Making |

| Color | Customers'Demand | Key words | Shoe Machine Industry |

| Shipping | 15days | After Warranty Service | Technical Video Support |

| Machine | Shoe Machine Line | DIMENSION | 500*235*195CM |

Customization