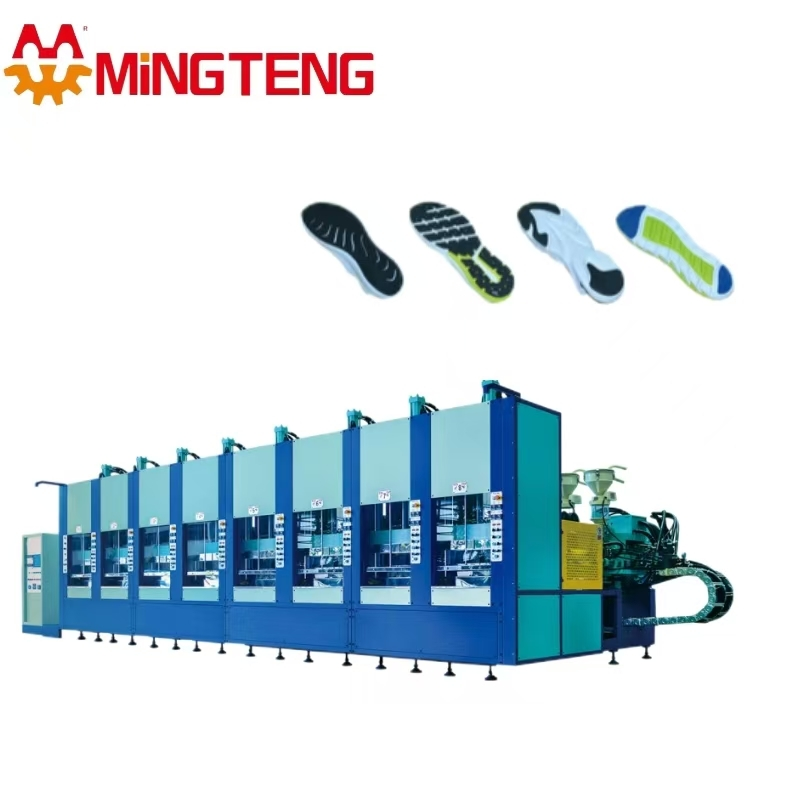

MT-8E4 Full-Automatic Foam EVA Injection Molding Machine

1. Injection System

EVA shoe sole injection moulding machine is controlled by PLC and PC system. Counting mechanism and potentiometer are used to work out the accurate quantity of material needed.

2. Mould Closing System

Its mould opening/closing is fast, and mould closing system is working in a hermetic unit.

3. Controlling System

Our EVA shoe sole injection moulding machine uses human-computer interaction interface and touch screen on basis of windows operation system. It is controlled in many aspects, including material rotate speed, injection quantity, infection time, injection temperature, sulfuring time and productivity. In PLC and PC controlling system, the machine is clear in function and convenient in operation.

1. Oil Hydraulic System

Proportional control valve is used to control oil pressure and flow in our EVA shoe sole injection moulding machine.

2. Energy Saving

Water-free heating plates in thermal insulation material can save energy greatly.

3. Others

According to Ergonomics, sole injection moulding machine is designed in low operation height. Besides, mould thickness adjusting is stepless, which is suitable to produce moulds in 100-260mm. It uses unique way to produce rubber material or EVA material.

Key attributes

| Applicable Industries | Manufacturing Plant,Other | Weight (KG)36000 | |

| Showroom Location | None | Video outgoing-inspection | Provided |

| Machinery Test Report | Provided | Marketing Type | Ordinary Product |

| Warranty of core components | 1 Year | Core Components | Engine,Bearing,Motor,Pressure vessel |

| Place of Origin | Fujian,China | Warranty | 1 Year |

| Condition | New | Brand Name | MingTeng |

| Brand | MT | Useful | Shoes Making |

| Color | Customers'Demand | Key words | Shoe Machine Industry |

| Shipping | 15days | After Warranty Service | Technical Video Support |

| Machine | Shoe Machine Line | DIMENSION | 1156*450*330CM |

Customization