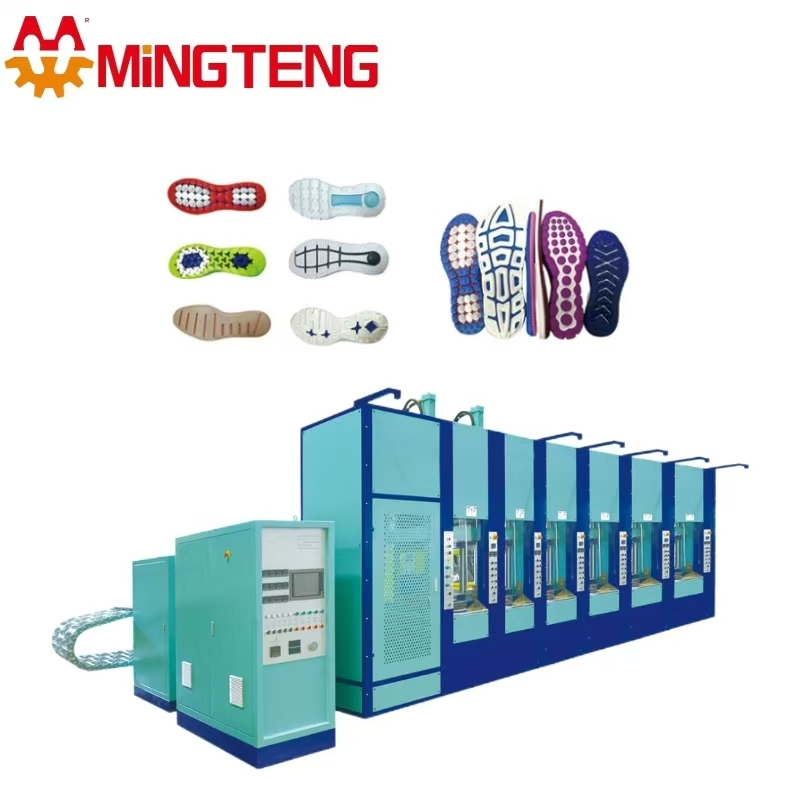

MT56-6E3 Full-Automatic Foam EVA Three-Color Injection Molding Machine

HYDRAULIC SYSTEM

Utilized three pumps work individually to reduce noise and enhance efficiency. Adopted proportion valve to coordinate the computer system, allowing precise control of the pressure and flow rate.

HYDRAULIC SYSTE

Utilized three pumps work individually to reduce noise and enhance efficiency. Adopted proportion valve to coordinate the computer system, allowing precise control of the pressure and flow rate.

ENERGY-CONSERVATION IS DESIGNED

No need water circulation for mould station, using efficient heat insulation material.

INJECTION SYSTEM

The Measuring mechanism utilzes potentiomter Detection and coordinates with the operation of PLC to control material quantity precisely. The two injectors move by applying worm gear deceletator conjoins brake motor to drive and the high speed movement is controlled by inverter,the position can be sensed by ultra-sonic wave linear displacement transducer accurately.

MOULD CLAMPING SYSTEM

The two-step speedy mould opening/closing mechanism with detecing device of fully mould closing. Low operation height, increased mould opening stroke, can apply to various style of moulds flexibly.

PC CONTROLLING SYSTEM

Utitlized industrial workstation computer in windows control system applying picture type of operation with touch screen to monitor the screw turning speed,injection volume time, injection tempterature, mould temperature, movement time and productivity on lie,easy to learn and operate.

Key attributes

| Applicable Industries | Manufacturing Plant,Other | Weight (KG) | 21000 |

| Showroom Location | None | Video outgoing-inspection | Provided |

| Machinery Test Report | Provided | Marketing Type | Ordinary Product |

| Warranty of core components | 1 Year | Core Components | Engine,Bearing,Motor,Pressure vessel |

| Place of Origin | Fujian,China | Warranty | 1 Year |

| Condition | New | Brand Name | MingTeng |

| Brand | MT | Useful | Shoes Making |

| Color | Customers'Demand | Key words | Shoe Machine Industry |

| Shipping | 15days | After Warranty Service | Technical Video Support |

| Machine | Shoe Machine Line | DIMENSION | 790*450*300CM |

Customization